- Published on

Improve gross profit: key inventory control actions in your warehouse or shop

- Author

Santiago Gonzalez

Santiago Gonzalez

When you're an entrepreneur or a small business owner, you often wear many hats at once: at one moment you're a worker 👷🏽♂️, later you're door-to-door selling 🏃🏽♀️, then you're researching 👩🏽🔬 and most of the time you're putting out fires 👩🏽🚒.

Today we're here to help you in your managerial role, with a crucial topic for the financial sustainability of your company: how to optimize inventory control to make better use of your working capital and increase your gross profit.

The actions we propose next are not a straitjacket; you can implement some now and others later. The important thing is that you lead your team in a philosophy of continuous improvement that will contribute to sustainability.

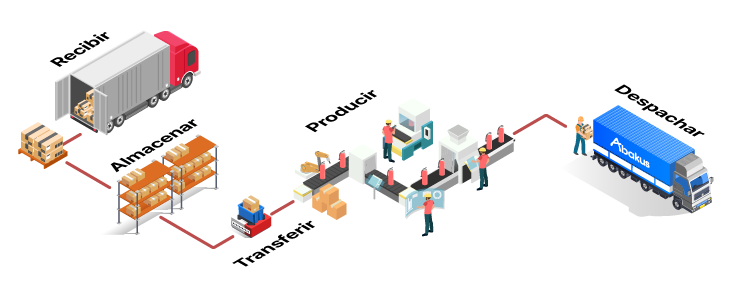

Organize product flows between warehouses, storage facilities, and units.

Goods that you sell, and materials that you use to produce them, take up physical space in your store. Even if you have only one point of sale with a warehouse in the back, it's important to know at all times where your units are to maintain an updated inventory and avoid losses.

If your company has warehouses, with dedicated storage areas, shelves, and responsible parties, the flows and movements of these products must be recorded in real time to understand the current location, transfer the real cost, and correctly calculate the gross profit of your operation in a given period.

To define the flows in your company, you can create a table, drawing, or diagram that identifies:

- Transactions with external parties

- Internal transactions

- Branches

- Warehouses and storage areas

- Equipment and their responsible parties

- Production units

Different types of transactions / movements occur between these locations, such as:

External

- Purchase orders and invoices

- Delivery notes

- Deliveries and dispatches

- Sales invoices

Internal

- Transfers/moves

- Internal consumption outputs

- Adjustments for loss/damage

- Production orders

Transfers or moves are internal movements that can occur between a branch and another, between a warehouse and a production area, or can even be temporary deliveries of equipment and tools to a work team.

Internal consumption of office products, supplies, and materials that are kept in inventory can be managed through output adjustments that unload inventory and at the same time assign the real cost of the products as a cost of sales in the month they are consumed.

To manage internal flows and have more detailed inventory control, it is ideal to implement an inventory and sales program that is easy to use, to keep the basics up to date: automatic entry of purchases and sales of units sold, counting and valuation of inventory, registration of transfers and movements, among others.

Analyze sales and consumption trends

How do you know how much inventory you should have to provide the best delivery times to your customers and keep your processes running smoothly?

That's a question that can only be answered through a thorough analysis of your sales history over a specific period to see variations and volume trends. Essentially, it's a trial-and-error process because, at first, you must have enough stock to meet the anticipated demand, but then you must modulate the minimum stock to avoid under or overstocking. We'll cover this in the next section.

For some companies and types of businesses, seasonality is important; in these scenarios, demand explodes at certain times (e.g., Christmas, school periods, special dates, etc.), and for this reason, they should not rely on monthly sales averages but rather on the same dates of previous periods/years to establish a direct comparison.

The analysis of sales trends gives us a key piece of information to calculate the reorder point: average daily sales, or units sold in a month in the case of low-rotation products.

Maintain optimal stock levels

Optimal stock levels are a bit like chasing the pot of gold at the end of the rainbow 🌈: you can get close, but it's always just "a little bit further". The market changes, new customers come in and increase volume, some leave and you're left with excess stock. The reality is that you need to constantly analyze your optimal stock level, and here are some tips to do it.

First, it's important to understand that the optimal stock level is the one that's high enough to avoid running out of units in the face of customer demand - understock - and low enough to avoid overstocking which will tie up your working capital by having products stored for a long time.

To achieve this, you need to understand your business and the particularities of your products: do they have expiration dates? Are they complex to manufacture? Are delivery times long due to imports or on-demand production? Are there conditions that suddenly explode demand (weather, events, etc.)? All these factors must be taken into account to define the reorder point we mentioned earlier, for which lead time (days) and safety stock (units) are required.

Another very important factor to include when calculating your optimal stock level is the price discount per unit offered by the supplier depending on the purchase volume. Sometimes - especially when storage space and working capital are not tight - it makes sense to buy and hold more stock if the unit price decreases significantly. This will help improve the gross margins of your sales and the overall profit of your company.

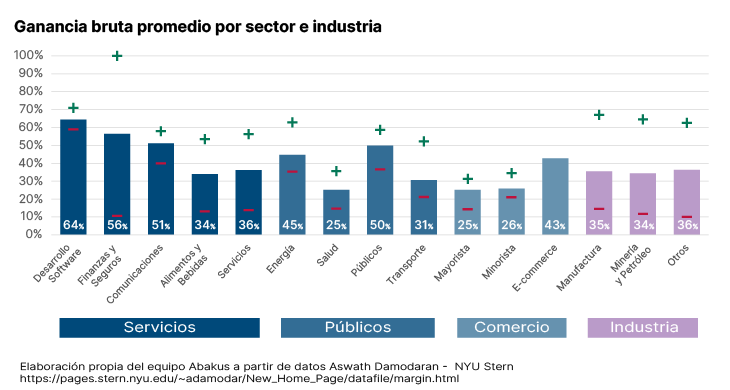

Increase your products' gross margins

Once you have better control over the optimal stock of your products, you can move on to the next level of analysis 🦸♀️: the key figure of gross profit margin for your products.

You should review this frequently - at least once every quarter - and if you find the figure is concerning, take quick corrective actions such as:

- Renegotiating prices with current suppliers

- Increasing purchase volumes

- Seeking new suppliers

- Optimizing production processes

- Reducing waste, losses, and damages

The gross profit margin varies between sectors and industries (and regions of the world), but a good reference is that it should be between 20-25% for general trade, between 40-45% for clothing and footwear production, and between 30-35% for industrial manufacturing.

Train and motivate your staff

To successfully implement any strategy, including the ones we mentioned, you must promote the core value of your company: your human team. It's important to see your employees as a human team, not just as human resources. This is not only because of what we have learned as a society about the most productive organizations, but also because by seeing them as a team, we can better understand their dynamics, interactions, collaboration, and communication.

In any business system, people are the key players who interact with each other, using technology to develop processes. This is how your internal system for managing inventory should work, no matter how simple your operation may be.

The people responsible for storage spaces, purchasing and replenishment, production, and sales must synchronize their different processes to improve the key figure of gross profit we mentioned earlier. In this case, the inventory management system is the technology that streamlines processes and facilitates interaction between people.

To add value to this chain, it is necessary to train them in the use of technologies and have clarity, at a team level, about the processes that determine tasks and responsibilities for each person and department. Additionally, gross profit and inventory turnover metrics can help set goals as a team and define bonuses based on achieving these goals.

Now it's your turn to start optimizing inventory in your company. Do you need guidance and support? Contact us!